Guide to Business Process Design & Analysis [With Examples]

By Mike Raia ![]() | Published June 19, 2019

| Published June 19, 2019

No time to read? Sit back and listen to this post.

Business Process Design, Analysis, and Examples

Today, we'll dive into the foundations of business process design from the ground up. Whether you are a beginner or a seasoned professional, this article will help you understand the basics of the business design process and provide some of the crucial steps in creating an effective strategy. Note: Check out our free BPM Guide for an even more thorough discussion of process planning and design. If you're looking for how to build a process with Integrify specifically, you can visit Creating a New Process with Integrify.

Related

What do we mean by "Process Design?"

For clarity about what exactly process design is, let's refer to Michael Hammer's definition in Harvard Business Review:

"...the specification of which people must perform what tasks, in what order, in what location, under what circumstances, with what information, and to what degree of precision."

This quote serves as an excellent reminder that a business process is more than a series of tasks; rather, it also encompasses the people, information, and procedures that feed the process. These must be considered in the process's design (or redesign).

Business Process Design Benefits

Properly designed business processes are the key to efficiency, scalability, and competitiveness. While working on either developing a process from the ground up or re-engineering an existing process, consider the following:

Properly designed business processes are the key to efficiency, scalability, and competitiveness. While working on either developing a process from the ground up or re-engineering an existing process, consider the following:

- By simply analyzing your processes (whether or not you intend to automate them), you begin to recognize redundancies, inefficiencies, areas of risk, lack of succession planning, and more. Business process analysis is core to improving how your business operates.

- Standardization helps in achieving consistency by benchmarking best practices across the organization.

- Implementing meaningful KPIs identifies areas of improvement, including bottlenecks, errors, and slow cycle times.

- It automates repetitive tasks to allow your employees to contribute in more meaningful, value-added ways that improve loyalty, engagement, and job satisfaction.

Business Process Design Example: The Pizza Shop Analogy

Business Process Design Example: The Pizza Shop Analogy

For one process design example, consider a pizza shop. It comprises a group of functions represented in a hierarchical map from the top down. This map will include all the tasks needed to run this fast-food chain, such as production, hiring, marketing, supply chain, etc. Each function is decomposed into the high-level processes that make up that function, then each of these high-level processes can be decomposed into more granular ones.

The production process could be divided into simpler sub-processes, such as preparing the dough and the sauce, cutting and placing the toppings, and baking and packing the pizza. Preparing the dough could be divided into even more granular steps, including all the ingredients needed, ideal storage conditions, etc. This exercise is repeated until the lowest level of processes or activities are reached to get a finalized and detailed process map of all the company's operations.

Any business and its processes can be broken down the same way. Think about something as simple as sending a letter, for example. Where do you keep the envelopes and the stamps? How do you apply the stamp? How do you seal the envelope, and where do you send it? Every part of a straightforward process that many of us do regularly can be broken down into its individual process steps. You can repeat this process analysis for any process design example you can think of.

Business Process Analysis: Laying the Foundation

A strong foundation is the key to your hard work, not crumbling down once you're almost at the finish line. Here are some cornerstones for your business process analysis:

- Establish and document the process hierarchy by walking through the system from the top down, as mentioned in the pizza chain process design example above.

- Break down the organization's functions and activities into more and more granular processes until the essential steps along the chain are reached. This will help identify improvement opportunities and isolate the root causes.

- Start the analysis one granular process at a time to achieve high effectiveness and efficiency. Identify areas to optimize and potential issues in the process, including redundancies, risky hand-offs, tribal knowledge,

- Develop a RACI (Responsibility, Accountability, Consulted, Informed) chart for each process task. Who is performing the job, who is approving the job was done correctly, who else has some involvement with the job, and who needs to know when the task is complete?

Remember that no changes should be implemented until you've worked your way back up to the highest level of processes, as changes to one granular process may impact others.

It might seem absurd to do each step for a single process instead of the organizational approach. Still, it is essential to employ this procedure even in single operations, especially for beginners or small businesses. It will propel you from a narrow path to a comprehensive approach, addressing the process as a critical link in a chain rather than a series of empty, ultra-divided parts. When working on one strategy, focusing on just one and disregarding others is easy. Not recognizing the connection between the elements could cause the process to fall short of effectiveness, efficiency, or both.

Critical Design Process Step: Problem Statement & Voice of the Customer

There isn't a better industry than manufacturing when defining, refining, and executing its processes. A vital tool methodology used in manufacturing is Six Sigma, one of the most effective process improvement methodologies, with the explicit goal of reducing variation in a process. A cornerstone technique of the Six Sigma methodology is DMAIC – an acronym for define, measure, analyze, improve, and control. In Six Sigma, defining is the most critical step, the first step, and usually the most time-consuming one. A project's success hinges on defining the problem correctly, which includes identifying why we are establishing the process. Does it add value, or could we do without it; who will the customers be for this internal and external process? Defining the problem makes or breaks the process.

There isn't a better industry than manufacturing when defining, refining, and executing its processes. A vital tool methodology used in manufacturing is Six Sigma, one of the most effective process improvement methodologies, with the explicit goal of reducing variation in a process. A cornerstone technique of the Six Sigma methodology is DMAIC – an acronym for define, measure, analyze, improve, and control. In Six Sigma, defining is the most critical step, the first step, and usually the most time-consuming one. A project's success hinges on defining the problem correctly, which includes identifying why we are establishing the process. Does it add value, or could we do without it; who will the customers be for this internal and external process? Defining the problem makes or breaks the process.

- Begin by considering the output of the process and what it needs to be.

- Define and document the requirements that must be delivered.

- Identify and document your stakeholders - regulators, other organizational functions (Human resources, IT, operations, sales, purchasing, etc.), and end customers.

- Work through the previously defined requirements, focusing on the minute details of the form in which it should be delivered and how to deliver on those requirements from there on to your customers.

Challenging some of the requirements is perfectly reasonable (and perhaps beneficial). Ask, "Does this step add value?" to avoid unnecessary costs, processes, and downright resource waste. For instance, in our previous business process design example of the pizzeria, a survey of our fictional customers showed that they'd prefer an efficient pizza delivery process that maintains the quality of the product and delivers it within 30 minutes of ordering. Analyzing this data and the number of potential customers in the area and other factors would help us identify how many delivery vehicles would be needed, the store's location, delivery policy, routes, etc.

Careful consideration of the customer's needs is a big part of defining the problem, as it informs the crucial requirements to be addressed and thus requires a closer look. There are several ways to collect quality responses from the various stakeholders, such as focus groups, requirements workshops, and brainstorming sessions. Whether you're engaging in a theoretical process design example or examining the genuine needs of your business, outline the must-have requirements based on your customer's needs and define what needs to be done (the process) to achieve those deliverables.

- Brainstorm with the different teams and involved personnel on the best way to achieve each step with the highest quality and the least amount of effort and resources used.

- Consider roles in executing the process, the data needed, where it is sourced, and the effort required to collect, report, and analyze it.

- Check if the process will be executed in different locations, along with other teams in various time zones, and account for any factors hindering the performance.

Design the process

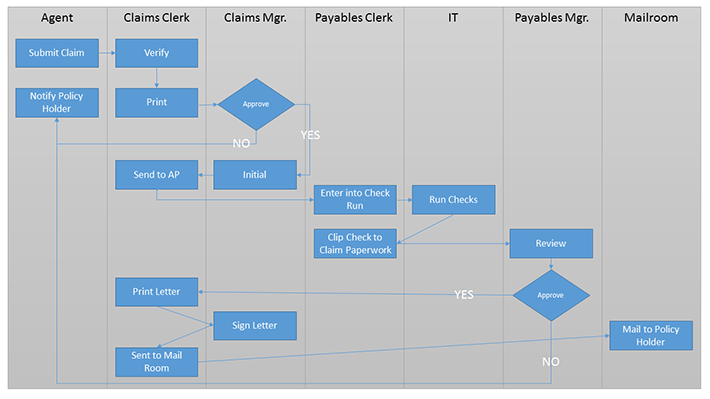

Now that all the ingredients to create and design an effective and efficient business process are there, you can begin with the actual design by mapping out the process. Mapping could be kick-started with a simple brainstorming exercise using a pen, post-it notes, and a whiteboard.

- Write down the inputs, outputs, and steps needed to achieve the business goal, each on a separate note.

- Create the process on the whiteboard (virtual or real) with post-its, each note containing the finest, most granular steps you can get down to.

- Draw the links between the different steps and how the process flows from one to the next.

- Once the initial process mapping is completed, several workshops will be carried out to identify any gaps in the design.

It will be beneficial to conduct some studies on the time it takes to move from one step to the next in the current process, as well as how long each step takes, and then come up with cycle and lead times. You aim to minimize the movement between stages, wait times, and overall waste in the process. An enormous benefit of using Post-it notes in an initial map is that you can move them around and recalculate how time-consuming the process would be and how much waste it would eliminate.

Once the whiteboard version is acceptable, move into documentation, which is essential for many reasons, such as training, future improvement initiatives, and regulatory and governmental requirements. A construction company wouldn't build a house without a blueprint, and that's exactly what the documentation should be—a guide for employees and stakeholders alike, so don't forget to document the inputs, steps, stakeholders, and required outputs as you go along.

Use the tools you feel comfortable with to design the finished business process. Visio is an industry standard, but there are various tools you can use, free and paid. We recommend several in this post. Give yourself plenty of room to work by placing steps/tasks far apart. You will undoubtedly move things around and need space to drop steps in between.

Rolling out the New Process

So you've designed a new process and think you're ready to unleash it on the organization. A successful new process rollout is doomed to fail if you don't consider its impact on the end users. Before you implement:

- Run workshops with a sample of the process's friendly but honest users and customers.

- Create different scenarios, assign the roles, and run through several process iterations as it was mapped initially.

- Collect feedback from the customers and people executing the process, and note what you may observe as inefficiencies or mistakes.

These activities will help you identify missing pieces of the puzzle and refine the process design before initiating a full-fledged implementation. Side note: It is also in the workshops where it becomes evident which tasks and steps are ripe for automation solutions. Repetitive jobs follow a defined logic and account for a large chunk of the effort and time in most business processes that can be automated using the various available automation solutions.

Summary

We covered a lot here, but if you want more, check out our free BPM Guide, which details many process design activities we described. If you're interested in an expert-led workshop for your company or departmental processes, Integrify offers a few different options.

Additional Resources

- Process design: an introduction to the perks and purpose

- Wikipedia Page for Process Design (It's pretty good!)

- Process Design (Management Study Guide)

- Business Process Design: Create an Optimized Process in 4 Steps

Tags

design a process process BPM planning Workflow

Categories

Project Management Business Ideas Workflow Ideas

Mike Raia

Marketing the world's best workflow automation software and drinking way too much coffee. Connect with me on LinkedIn at https://www.linkedin.com/in/michaelraia/